Metal Sheet Tin: A Versatile Solution for Modern Industries

Jan 26, 2024|

Jan 26, 2024| View:98

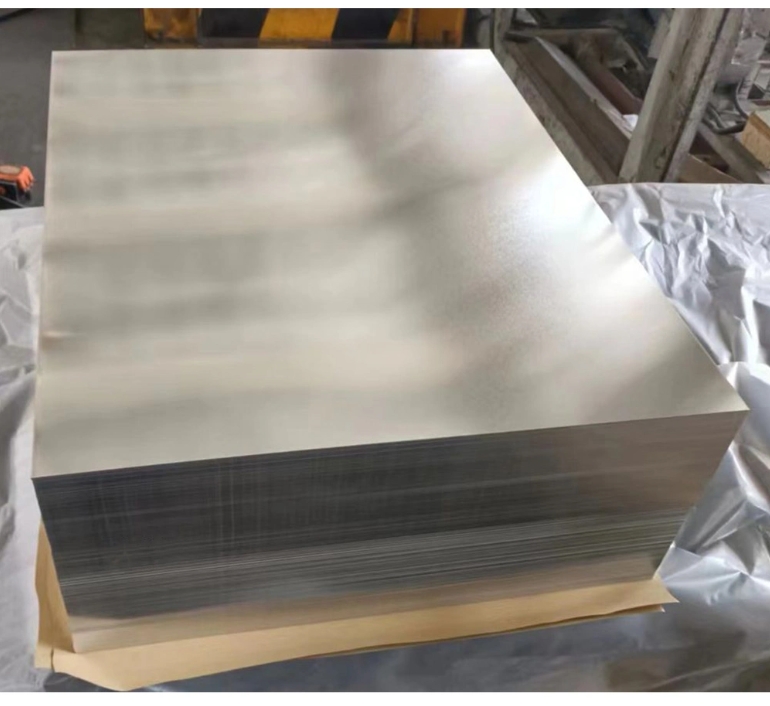

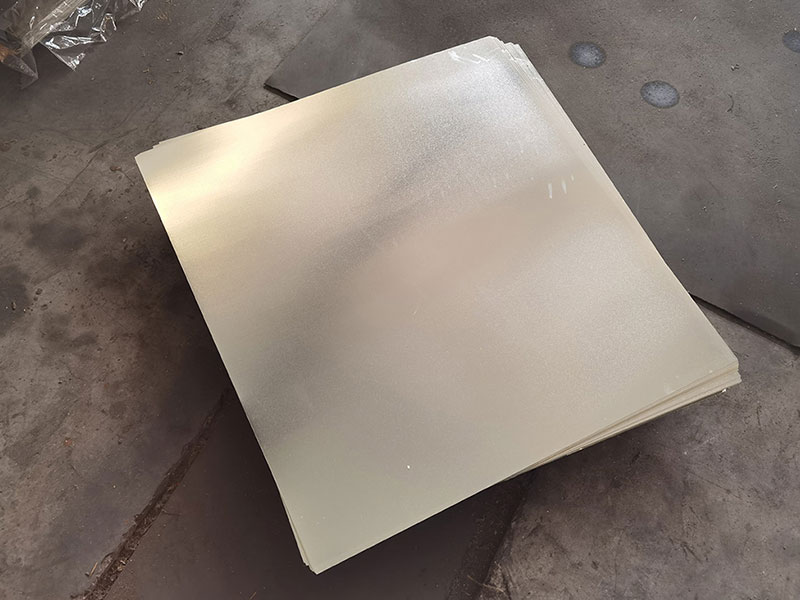

View:98Sheet tin is a thin sheet made of tin that has a certain thickness and plasticity. Tin is a metallic element with a silver-white appearance and good corrosion resistance. It is famous for its ductility and corrosion resistance.Metal sheet tin in the form of rolls or flat sheets, and its thickness can be determined according to the specific requirements. Change according to needs.

Metal Sheet Tin Compared To Other Metals

1.Corrosion Resistance

One of the significant advantages of metal sheet tin is its exceptional resistance to corrosion. Unlike iron or steel, which are prone to rusting, tin is highly resistant to oxidation, making it suitable for applications that involve exposure to moisture or harsh environments.

2. Malleability and Formability

Metal sheet tin possesses excellent malleability and formability. It can be easily bent, shaped, or formed into intricate designs without cracking or breaking. This property makes it ideal for applications where complex shapes or fine details are required.

3. Low Melting Point

Tin has a relatively low melting point compared to many other metals. It melts at around 232 degrees Celsius (449 degrees Fahrenheit). This low melting point allows for easy soldering and joining with other metals, making it a preferred choice in the electronics industry for soldering connections on circuit boards.

4. Solderability

Metal sheet tin exhibits excellent solderability. It forms strong bonds with other metals when heated and allows for reliable and durable soldered connections. This property makes it widely used in electronic components and circuitry.

5.Aesthetic Appeal

Metal sheet tin has a distinct silvery-white appearance, which adds to its aesthetic appeal. It is often used in decorative applications, such as ornamental pieces, architectural accents, and art projects, where its lustrous finish enhances the visual appeal of the final product.

6.Environmental Benefits

Tin is a non-toxic and environmentally friendly metal. It is widely recognized as safe for food contact, making it suitable for packaging applications. Additionally, tin is recyclable, allowing for the conservation of resources and reducing environmental impact.

Manufacturing Process and Properties of Metal Sheet Tin

1.Refining and Extraction

The primary source of tin is cassiterite ore, which is mined from underground or open-pit mines. The ore is then processed to remove impurities and refined to obtain pure tin metal. This refining process typically involves techniques such as smelting or electrolytic refining.

2.Rolling and Forming

Once the tin metal is obtained, it is transformed into thin sheets through a rolling process. The metal is heated and passed through a series of rollers that gradually reduce its thickness to the desired level. This rolling process can be repeated multiple times to achieve the desired thickness and uniformity.

3.Physical Properties

Metal sheet tin exhibits several physical properties that make it suitable for various applications. It has a smooth and shiny surface, lending it a silvery appearance. The sheets are typically lightweight and offer good ductility, allowing them to be easily bent, formed, or shaped into different configurations without cracking or breaking.

4.Chemical Properties

Tin is known for its excellent resistance to oxidation and corrosion. It forms a protective oxide layer on its surface, which helps prevent further oxidation and enhances its durability. This property makes metal sheet tin suitable for applications where exposure to moisture, chemicals, or corrosive environments is a concern. Tin is also relatively stable in air and does not tarnish easily.

5.Solderability

Metal sheet tin has exceptional solderability, which refers to its ability to form strong bonds with other metals when heated. This property is crucial in soldering applications, where tin is commonly used to create reliable and durable connections between electronic components or circuitry.

6.Recyclability

Metal sheet tin is a recyclable material, meaning it can be melted down and reused to create new products. This recyclability contributes to the conservation of resources and reduces the environmental impact associated with its production.

Applications of Metal Sheet Tin

1.Packaging

Metal sheet tin is extensively used in the packaging industry, particularly for food and beverage containers. Tin cans provide an impermeable and protective barrier, ensuring the preservation and freshness of the packaged products. Tin-plated steel is often employed to create tin cans, lids, and closures.

2. Electronics

Metal sheet tin plays a crucial role in the electronics industry. It is commonly used for soldering connections on circuit boards, ensuring reliable electrical conductivity and secure joints. Tin's low melting point and excellent solderability make it a preferred choice for electronic component encapsulation and surface mount technology.

3. Roofing and Construction

Metal sheet tin is utilized in the construction industry for various applications. It is commonly employed for roofing materials, thanks to its corrosion resistance and durability. Tin sheets are also used for cladding, gutters, downspouts, and decorative architectural elements, providing both functionality and aesthetic appeal.

4. Arts and Crafts

Metal sheet tin is a popular material in arts and crafts due to its malleability and attractive appearance. It can be easily cut, shaped, and formed into intricate designs, making it ideal for creating sculptures, jewelry, ornaments, and decorative items.

5. Automotive Industry

Metal sheet tin finds applications in the automotive sector as well. Tin-coated steel is used for manufacturing fuel tanks, exhaust systems, and various automotive components. The corrosion resistance of tin helps protect these parts from environmental elements and extends their lifespan.

7.Chemical and Industrial Applications

Metal sheet tin's resistance to corrosion and chemical reactions makes it suitable for use in chemical plants, laboratories, and industrial settings. It is employed for lining tanks, vats, and containers that store corrosive substances. Tin also finds applications in electroplating, soldering fluxes, and the production of certain chemicals.

8.Food and Beverage Industry

Metal sheet tin's non-toxic and food-safe properties make it an ideal choice for food and beverage applications. It is used for manufacturing tin-plated steel cans for canned foods, beverage cans, and metal closures. Tin's resistance to corrosion helps maintain the quality and safety of packaged food and beverages.

Metal sheet tin plays a vital role in modern industries due to its unique properties and versatile applications. Its corrosion resistance, formability, and solderability make it an ideal choice for diverse sectors such as packaging, electronics, construction, and art. As a reliable solution, metal sheet tin continues to contribute to the advancement of technology, offering innovative possibilities and ensuring the longevity of various products.